ZBJ-CY Briquette Machines

Briquette Machines-CY

Basic info:

The series Mechanical Stamping briquette machines offered by KINGMAN(KMEC) are newly designed with an integrated function, featuring high yield of pellets production and briquettes production based upon different moulds (also called forming dies) put into use.

The series consist of belt loading type and screw loading type.

Advantages:

Forestry waste: wood shavings, bagasse, pomace, pulp sludge, pasture, bark, bamboo shavings, sawdust, leather scraps, etc.

All the raw materials above can be processed into pellets and briquettes, with a higher fuel value suitable for domestic fireplaces, small and medium sized biomass boilers and industrial power and heating productions.

Parameter table:

Belt loading type

Mould (die) parameter table (taking sawdust as feedstock with the moisture content of 15%)

Screw loading type

Mould (die) parameter table (taking sawdust as feedstock with the moisture content of 15%)

--------------------------------------------------------------------------------------------------------------------------------------------------

Link to related products hereunder:

Hydraulic Briquette Machine Screw Type Briquette Machine

Basic info:

The series Mechanical Stamping briquette machines offered by KINGMAN(KMEC) are newly designed with an integrated function, featuring high yield of pellets production and briquettes production based upon different moulds (also called forming dies) put into use.

The series consist of belt loading type and screw loading type.

Advantages:

- Alternative power supply: the ZBJ-CY series machines can be driven by either electric motor or diesel engine to meet the demands from different clients.

- Combined with automatic auxiliary equipment, the briquetting productivity can be enhanced impressively.

- Alternative finished products: different from ZBJ-YK Series and ZBJ-YY Series briquetting presses, the series briquette machines can produce either biomass pellets or briquettes. KINGMAN(KMEC) is capable of offering clients with either pellet die or briquette die to fulfill requirements from a wider scope of customers.

- An extensive spectrum of material application: both agro and forestry waste can be manufactured by the series briquette machines. Namely, as follows:

Forestry waste: wood shavings, bagasse, pomace, pulp sludge, pasture, bark, bamboo shavings, sawdust, leather scraps, etc.

All the raw materials above can be processed into pellets and briquettes, with a higher fuel value suitable for domestic fireplaces, small and medium sized biomass boilers and industrial power and heating productions.

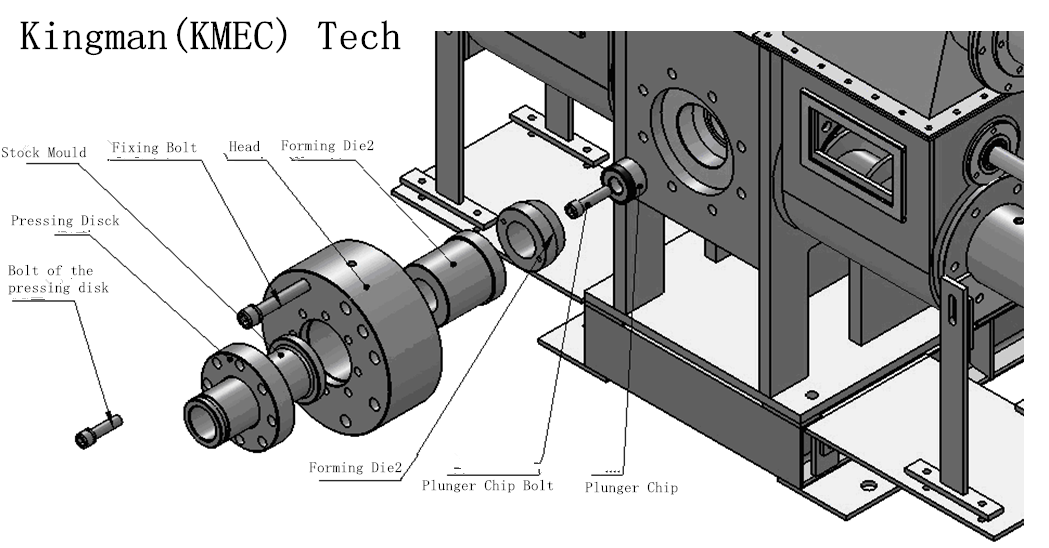

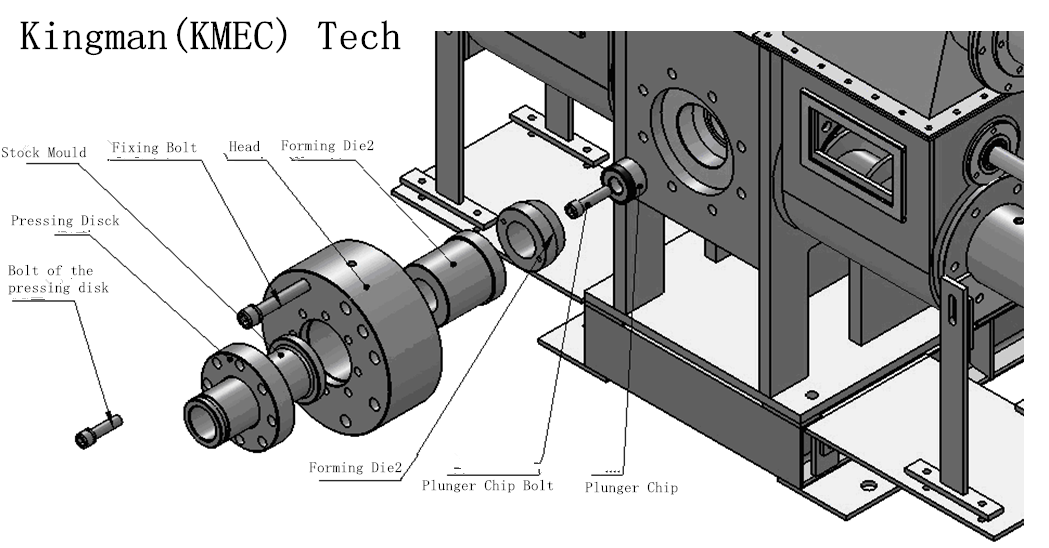

- Long service period: made of special alloy steel feature high degree of wear resistance, the mould lifespan can be utterly prolonged.

- Of the series, 2 main types of briquette press can be chosen: the extruding briquette machines with abrasive disc and the mechanical stamping briquetting machines. The abrasive disc extruding type can generally be further divided into three kinds: Ring die design, flat plate design, and ring & flat die design. The diameter of briquettes produced by abrasive disc extruding briquette machines is 30mm * 30mm, while the diameter of mechanical stamping briquetting presses can reach 80mm.

- Moreover, the shape of mechanical stamping briquettes is diverse, round, square, hexagonal, perforated and other tailored forms.

Parameter table:

Belt loading type

| Model | Output (kg/h) | Main Engine Size (mm) | Weight (kg) | Total Power (kg) | Finished Fuel Rod's Diameter (mm) |

| ZBJ-CYB500 | 500 | 3200*1500*1500 | 4500 | 35 | φ50 |

| ZBJ-CYB1000 | 1000 | 3200*1500*1500 | 7000 | 61.5 | φ70/φ30/φ22/φ10/φ8 |

Mould (die) parameter table (taking sawdust as feedstock with the moisture content of 15%)

| Model (pore size) | 8mm | 10mm | 22mm | 30mm | 70mm |

| Pore number | 61 | 37 | 7 | 4 | 1 |

| Capacity (kg) | 950kg | 900kg | 820kg | 880kg | 1200kg |

Screw loading type

| Model | Output (kg/h) | Main Engine Size (mm) | Weight (kg) | Total Power (kg) | Finished Fuel Rod's Diameter (mm) |

| ZBJ-CYS500 | 500 | 3200*1500*1500 | 4000 | 35 | φ50 |

| ZBJ-CYS1000 | 1000 | 3400*2000*1800 | 7000 | 61.5 | φ70/φ30/φ22/φ10/φ8 |

Mould (die) parameter table (taking sawdust as feedstock with the moisture content of 15%)

| Model (pore size) | 8mm | 10mm | 22mm | 30mm | 70mm |

| Pore number | 61 | 37 | 7 | 4 | 1 |

| Capacity (kg) | 950 | 900 | 820 | 880 | 1200 |

--------------------------------------------------------------------------------------------------------------------------------------------------

Link to related products hereunder:

Hydraulic Briquette Machine Screw Type Briquette Machine

Related Products:

Products

- XP Drum Chipper

- FSJII broyeuse a marteau

- broyeuse a marteau

- HGJ Drying System

- SSJ serie de convoyage

- ZBJ-YK Briquette Machines

- ZBJ-CY Briquette Machines

- ZBJ-YY Hydraulic Briquette Machines

- Packing Machine

- THL Carbonizing Furnace

- BPJ Barking Machine

- Presse a ball-MFJF

- presse a ball-TLSG

- Presse a ball-GFKF

- Presse a ball-TFMTF

- Presse renforce a ball

- presse a ball-TS

- Presse a ball-JY

- presse a ball-GY

English

English  Русский

Русский  Español

Español