ZBJ-YY Hydraulic Briquette Machines

Briquetting Presses-YY

Basic info:

Parameter table:

Introductions:

1. Application:

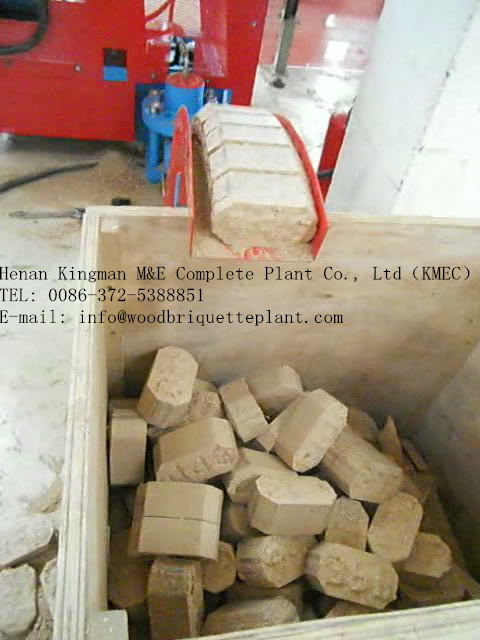

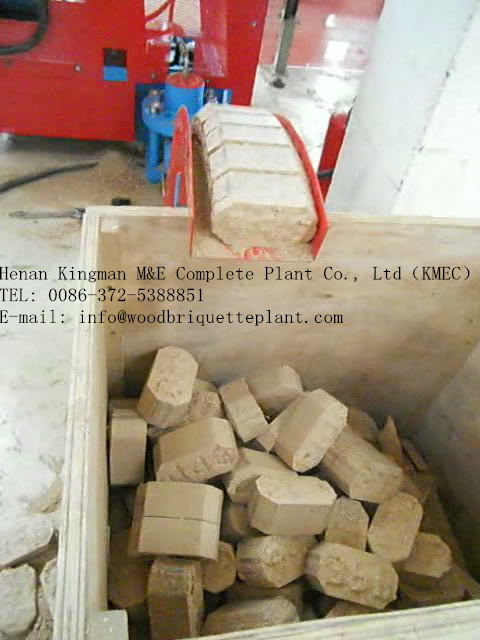

Briquetting all kinds of wood waste, straw residues, waste paper, plastics to large masses. Briquettes are high density bio-energy products.

Briquettes shapes: rectangle, octagon, hexagon, round, etc.

2. Characteristic:

1> High-performance hydraulic propelling device allows briquettes to be tightly compacted with smooth surface, durable usage and to be carried and stored simply.

2> Briquettes shapes can be designed based on customers’ requirements.

3> High strength hydraulic system can supply sufficient compressing drive. And with its cooling system, machine can run sufficiently.

4> Imported material and high wear resistant pressure cylinder.

5> Automatic rotating extractor feeds constantly to ensure stable and sustainable production.

6> Briquettes’ thickness can be adjusted.

7> Wood wastes and straw stalk can be pressed into briquettes.

8> Same quality and performance as European standards yet at a lower price.

9> Company’s logo can be engraved on the briquettes by designing briquette presses specially.

3. Quality Guarantee Terms

Quality guarantee term extends for one year. Any broken parts caused by the machine-itself and inner quality flaws will be offered with replacement from KINGMAN. Other problems which are caused by operation mistakes, man-made problems, etc will be due to the customer.

4. Electricity situation

All of the machines listed above are matched with Chinese Standards upon electricity situation: 380 Volts, 50Hz, 3 phases. If you have special electricity requirements on the machines, extra costs of electricity triggered by the special requirements shall be paid.

--------------------------------------------------------------------------------------------------------------------------------------------------------

Link to other briquette machines hereunder:

Basic info:

- The KINGMAN(KMEC)-YY series briquetting presses put into use a high-performance hydraulic propelling device which is well-known for extruding biomass pellets with highly compacted structure, featuring durability, smooth surface and various different shapes.

- Equipped with a pressure cylinder made from top-notch steel and highly wear resistant. Besides, the automatic rotating extractor can keep the feeding constantly and ensure stable production.

- The scope of material application also covers straw residues, wasted papers, sawdust, wasted clothes and other wood or biomass wastes.

- The KINGMAN(KMEC)-YY hydraulic briquetting press can produce biomass briquettes in hexagon, round, octagon and various other shapes, with the thickness of the briquettes adjustable. And briquettes with customized shape are also achievable. Furthermore, moulds can be manufactured in a customized way according to your requests.

Parameter table:

| Model | Basic Data |

|

ZBJ-YY100 Single tube |

Capacity: 100-125 kg/h Power: 7.5KW Size: L1960 x W1880 x H1950mm Weight: 1200kg |

|

ZBJ-YY200 Single tube |

Capacity: 200-250 kg/h Power: 15 KW Size: L1960 x W1880 x H1950mm Weight:1700kg |

|

ZBJ-YY400 Double tube |

Capacity: 400-500 kg/h Power: 37 KW Size: L2000 x W2000 x H2100mm Weight: 4500kg |

|

ZBJ-YY800 Double tube |

Capacity: 800-1000 kg/h Power:75 KW Size: L2700 x W2200 x H2300mm Weight: 6800kg |

Introductions:

1. Application:

Briquetting all kinds of wood waste, straw residues, waste paper, plastics to large masses. Briquettes are high density bio-energy products.

Briquettes shapes: rectangle, octagon, hexagon, round, etc.

2. Characteristic:

1> High-performance hydraulic propelling device allows briquettes to be tightly compacted with smooth surface, durable usage and to be carried and stored simply.

2> Briquettes shapes can be designed based on customers’ requirements.

3> High strength hydraulic system can supply sufficient compressing drive. And with its cooling system, machine can run sufficiently.

4> Imported material and high wear resistant pressure cylinder.

5> Automatic rotating extractor feeds constantly to ensure stable and sustainable production.

6> Briquettes’ thickness can be adjusted.

7> Wood wastes and straw stalk can be pressed into briquettes.

8> Same quality and performance as European standards yet at a lower price.

9> Company’s logo can be engraved on the briquettes by designing briquette presses specially.

3. Quality Guarantee Terms

Quality guarantee term extends for one year. Any broken parts caused by the machine-itself and inner quality flaws will be offered with replacement from KINGMAN. Other problems which are caused by operation mistakes, man-made problems, etc will be due to the customer.

4. Electricity situation

All of the machines listed above are matched with Chinese Standards upon electricity situation: 380 Volts, 50Hz, 3 phases. If you have special electricity requirements on the machines, extra costs of electricity triggered by the special requirements shall be paid.

--------------------------------------------------------------------------------------------------------------------------------------------------------

Link to other briquette machines hereunder:

Related Products:

Products

- XP Drum Chipper

- FSJII broyeuse a marteau

- broyeuse a marteau

- HGJ Drying System

- SSJ serie de convoyage

- ZBJ-YK Briquette Machines

- ZBJ-CY Briquette Machines

- ZBJ-YY Hydraulic Briquette Machines

- Packing Machine

- THL Carbonizing Furnace

- BPJ Barking Machine

- Presse a ball-MFJF

- presse a ball-TLSG

- Presse a ball-GFKF

- Presse a ball-TFMTF

- Presse renforce a ball

- presse a ball-TS

- Presse a ball-JY

- presse a ball-GY

English

English  Русский

Русский  Español

Español