HGJ Drying System

Drying Equipment

Composed mainly of burner (which can be designed to use different materials, for example it can use either biomass or homemade combustible gas as fuel), draught fan, pipeline and cyclone, HGJ-I Series drying system is characteristic of high drying volume and efficient waste disposal. The system features low labor investment and energy consumption.

Hot air produced from the burner will flow into pipe mingling with feedstock due to the whopping suction strength by the fan, during which moisture within feedstock will decrease.

Drying effect is generally impacted by original moisture content of feedstock and feeding speed, and also size of feedstock. Therefore, you should take into consideration of the aforesaid factors when drying material.

Parameter Table:

Note: Moisture content of raw material shall remain around 20% to 50%.

Reminder:

As for drying system, the part cannot be ignored. Otherwise, briquetting effect will be adversely influenced. Take briquetting as example, requirement for moisture content shall remain about 10%-12%, and either higher or lower content may result in no formation of briquettes or low quality. In this regard, drying is an imperative step to go.

For briquetting, if the original moisture content of feedstock before taken in the drying system stays above 50%, then the material may not be dried in a single time, two-time drying will be necessary.

KINGMAN(KMEC) will design the drying system based upon the information offered by clients. KINGMAN(KMEC) is willing to help clients turn waste material into actual profits with the wholehearted services.

It, as the main body of the drying section, is associated with stove, pipeline, draught fan, loader and other accessory equipment. During the process, raw material under the work of fan will scatter sufficiently within the drum to contact with hot blast air and then steamed moisture following the air thrust force will be ventilated.

Features

1. Drum dryer models can be chosen from single drum, bi-layer drum, triple layer one.

2. Highly mechanized, high throughput and continuous running.

3. Elegant structure design (low resistance against flow through the pipeine), simple operation, low maintenance costs and decreased power consumption.

4. A wide range of application

5. Uniform production and stable performance and high thermal efficiency (generally up to 80% -90%)

In the process of drying, stability of the roller and uniformity of the airflow will enjoy a full play, with the drum and connected pipeline conveying materials effectively. Thanks to the above principle, drying intensity is increased yet labor investment reduced.

Parameter table:

Note:

Drum dryer is commonly used in the field of agricultural industry and biomass energy, as an ideal adds-on for large-sized biomass by-product complete plants.

The Twin Boiler Drying system provided by KINGMAN(KMEC) does have its own unique characters, even comparing with HGJ-I Series and HGJ-II Series drying systems.

HGJ-III drying unit is designed with a pair of boilers to quicken and maximize drying efficiency. The output moisture will fall down to 8%-12% from the original above 50%. Either of the two boilers can be chosen if the original moisture of raw material is not so high. And the option goes resilient.

Working principles:

Under the work of high speed hot air, moist material will disperse swiftly when put inside, the drying area thus will be extended. Material billowed drastically in the drying unit will then be desiccated constantly. Due to the short time of contact between hot air current and feedstock, the drying time lasts just about 1 to 5 seconds through the entire system. KINGMAN(KMEC) having taken the high temperature into consideration adopts heat-resistant and insensitive components to compose the system.

As for the fuel application, the type of fuel can be chosen according to the clients’ requirements. But usually, the scope of fuel covers biomass residuals, besides, gas burner, coal-fired air furnace or steam heat exchanger can be offered by KINGMAN(KMEC).

Parameter table:

- HGJ-I Series Drying system

Composed mainly of burner (which can be designed to use different materials, for example it can use either biomass or homemade combustible gas as fuel), draught fan, pipeline and cyclone, HGJ-I Series drying system is characteristic of high drying volume and efficient waste disposal. The system features low labor investment and energy consumption.

Hot air produced from the burner will flow into pipe mingling with feedstock due to the whopping suction strength by the fan, during which moisture within feedstock will decrease.

Drying effect is generally impacted by original moisture content of feedstock and feeding speed, and also size of feedstock. Therefore, you should take into consideration of the aforesaid factors when drying material.

Parameter Table:

| Model | HGJ-I-200 | HGJ-I-500 | HGJ-I-800 |

| Capacity(Kg/hour) | 200-250KG | 500-700KG | 800-900KG |

|

Size of Input Material (Dia.) |

< 3mm & < 5mm | < 3mm & < 5mm | < 3mm & < 5mm |

| Temperature of Hot Air | 180°C~250°C | 180°C~250°C | 180°C~250°C |

| Consumption of Wood Waste | 15-20 kg/h | 30-35kg/h | 30-35kg/h |

|

Power (Centrifugal Fan) |

4kw | 7.5kw/11kw+1.5kw | 11kw+1.5kw+0.75kw |

| Net/Gross Weight | 700/800kg | 1800/1900kg | 2110/2280kg |

| Dimension(m) | 6×2×3.65m | 11×2×3.65m | 11×2×3.65m |

Reminder:

As for drying system, the part cannot be ignored. Otherwise, briquetting effect will be adversely influenced. Take briquetting as example, requirement for moisture content shall remain about 10%-12%, and either higher or lower content may result in no formation of briquettes or low quality. In this regard, drying is an imperative step to go.

For briquetting, if the original moisture content of feedstock before taken in the drying system stays above 50%, then the material may not be dried in a single time, two-time drying will be necessary.

KINGMAN(KMEC) will design the drying system based upon the information offered by clients. KINGMAN(KMEC) is willing to help clients turn waste material into actual profits with the wholehearted services.

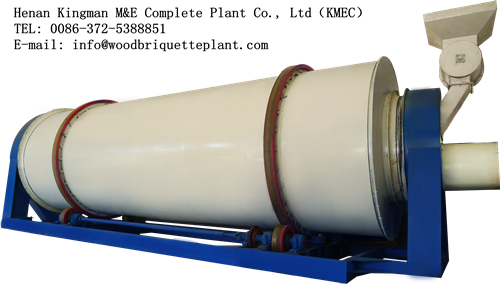

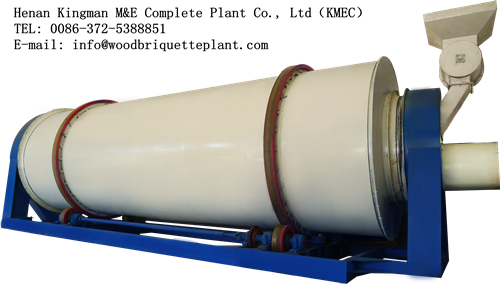

- HGJ-II Series Rotary Drum Dryer

It, as the main body of the drying section, is associated with stove, pipeline, draught fan, loader and other accessory equipment. During the process, raw material under the work of fan will scatter sufficiently within the drum to contact with hot blast air and then steamed moisture following the air thrust force will be ventilated.

Features

1. Drum dryer models can be chosen from single drum, bi-layer drum, triple layer one.

2. Highly mechanized, high throughput and continuous running.

3. Elegant structure design (low resistance against flow through the pipeine), simple operation, low maintenance costs and decreased power consumption.

4. A wide range of application

5. Uniform production and stable performance and high thermal efficiency (generally up to 80% -90%)

In the process of drying, stability of the roller and uniformity of the airflow will enjoy a full play, with the drum and connected pipeline conveying materials effectively. Thanks to the above principle, drying intensity is increased yet labor investment reduced.

Parameter table:

| Model | Diameter (mm) | Length (m) | Power(kw) | Speed of Rotation (rpm) |

| HGJ-II-6 | 600 | 4,5,6,7,8 | 3-5.5 | 3-20 adjustable |

| HGJ-II-8 | 800 | 4,5,6,7,8,9,10 | 5.5-7.5 | 3-20 adjustable |

| HGJ-II-10 | 1000 | 6,7,8,9,10,11,12 | 5.5-7.5 | 3-20 adjustable |

| HGJ-II-12 | 1200 | 6,8,10,12,14,16 | 7.5-11 | 3-20 adjustable |

| HGJ-II-15 | 1500 | 8,10,12,14,16,18 | 11-15 | 3-20 adjustable |

| HGJ-II-18 | 1800 | 8,10,12,14,16,18,20 | 15-18.5 | 3-20 adjustable |

| HGJ-II-22 | 2200 | 10,12,14,16,18,20,22,25 | 18.5-22 | 3-20 adjustable |

| HGJ-II-24 | 2400 | 12,14,16,18,20,22,25 | 22-30 | 3-20 adjustable |

Note:

Drum dryer is commonly used in the field of agricultural industry and biomass energy, as an ideal adds-on for large-sized biomass by-product complete plants.

- HGJ-III Twin Boiler Drying Unit

The Twin Boiler Drying system provided by KINGMAN(KMEC) does have its own unique characters, even comparing with HGJ-I Series and HGJ-II Series drying systems.

HGJ-III drying unit is designed with a pair of boilers to quicken and maximize drying efficiency. The output moisture will fall down to 8%-12% from the original above 50%. Either of the two boilers can be chosen if the original moisture of raw material is not so high. And the option goes resilient.

Working principles:

Under the work of high speed hot air, moist material will disperse swiftly when put inside, the drying area thus will be extended. Material billowed drastically in the drying unit will then be desiccated constantly. Due to the short time of contact between hot air current and feedstock, the drying time lasts just about 1 to 5 seconds through the entire system. KINGMAN(KMEC) having taken the high temperature into consideration adopts heat-resistant and insensitive components to compose the system.

As for the fuel application, the type of fuel can be chosen according to the clients’ requirements. But usually, the scope of fuel covers biomass residuals, besides, gas burner, coal-fired air furnace or steam heat exchanger can be offered by KINGMAN(KMEC).

Parameter table:

| Model | HGJ-III-400 | HGJ-III-500 | HGJ-III-900 |

| Capacity(Kg/hour) | 400-500KG | 500-700KG | 900-1000KG |

|

Size of Input Material (Diameter) |

< 3mm & < 5mm | < 3mm & < 5mm | < 3mm & < 5mm |

| Temperature of Hot Air | 180°C~250°C | 180°C~250°C | 180°C~250°C |

| Consumption of Wood Waste | 60kg/h | 100kg/h | 150kg/h |

| Moister content max % | 20-50% | 20-50% | 20-50% |

| Moisture of material after drying | 8-12% | 8-12% | 8-12% |

|

Power (Air Fan+Air Lock+ speed adjustable feed motor) |

7.5kw+0.75kw +0.75kw |

11kw+0.75kw +0.75kw |

15kw+0.75kw+0.75kw |

| Net/Gross Weight | 2040/2260kg | 2850/3080kg | 2850/3080kg |

| Overall dimension(L*W*H) | 9m*2.4m*4m | 9m*3.2m*4m | 9.5m*3.8m*4.5m |

| Packing size | 11 M3(3 cases) | 14 M3(3 cases) | 18 M3(3 cases) |

Related Products:

Products

- XP Drum Chipper

- FSJII broyeuse a marteau

- broyeuse a marteau

- HGJ Drying System

- SSJ serie de convoyage

- ZBJ-YK Briquette Machines

- ZBJ-CY Briquette Machines

- ZBJ-YY Hydraulic Briquette Machines

- Packing Machine

- THL Carbonizing Furnace

- BPJ Barking Machine

- Presse a ball-MFJF

- presse a ball-TLSG

- Presse a ball-GFKF

- Presse a ball-TFMTF

- Presse renforce a ball

- presse a ball-TS

- Presse a ball-JY

- presse a ball-GY

English

English  Русский

Русский  Español

Español